OUR SPECIALISATIONS

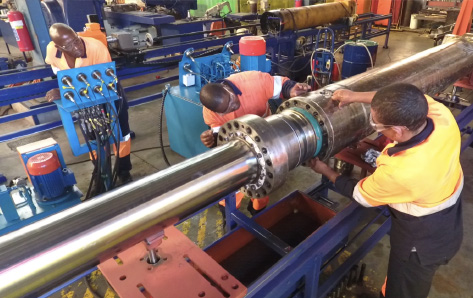

We specialise in repairing and remanufacturing hydraulic cylinders on remote sites.

This includes:

CYLINDER INSPECTION

Strip, clean, inspect and quote onsite.

SPECIALISED ROD CHROME REPAIR

We repair the rod chrome using a specialised welding process. In the event that the rod is severely damaged, we can re-rod.

ACCURATE BARREL AND ROD SURFACE FINISH CONTROL

SPECIALISED BARREL REPAIR

We specialise in honing oversize and resizing the cylinder parts to suit, whilst still using the original seal design. In the event that the barrel is severely damaged, we can re-tube.

PRESSURE TEST ONSITE

500 Bar capacity with multi stroke distance testing.

ASSEMBLE ONSITE

Easy and accurate assembly reducing the risk of seal damage.

HARD CHROME PLANT

CHROME PLANT WITH 5,5M TANK to be set up in West Africa.

ALL OF THE ABOVE IS COVERED BY OUR STANDARD WARRANTY.

With the ability to strip and inspect failures onsite, the customer can immediately evaluate the cause of failure and prevent further downtime from:

- Pump failure system contamination.

- Physical damage caused by equipment abuse or operational errors.

- Quick cylinder repair reduces down time and the amount of swing stock required.